Aluminium 6061-T6 is a high-strength, lightweight alloy known for its excellent mechanical properties, versatility, and good strength-to-weight ratio, making it ideal for aerospace, transportation, and construction applications.

1.1 Overview of Aluminium 6061-T6 Alloy

Aluminium 6061-T6 is a heat-treatable alloy with magnesium and silicon as primary alloying elements, offering excellent strength, corrosion resistance, and weldability. It is widely used in aerospace, automotive, and construction industries due to its high strength-to-weight ratio, durability, and versatility in various applications, making it one of the most popular aluminium alloys for structural and mechanical components worldwide.

1;2 Importance of Aluminium 6061-T6 in Industrial Applications

Aluminium 6061-T6 is crucial in industrial applications due to its high strength, excellent machinability, and corrosion resistance. It is widely used in aerospace for aircraft components, in automotive for lightweight parts, and in construction for structural frameworks. Its versatility, durability, and cost-effectiveness make it a preferred choice for industries requiring high-performance materials, ensuring reliability and efficiency in diverse environments and applications.

Chemical Composition of Aluminium 6061-T6

Aluminium 6061-T6 consists of magnesium, silicon, and traces of iron, copper, and chromium, providing strength, durability, and corrosion resistance. Its balanced composition meets ASTM and EN standards.

2.1 Key Alloying Elements (Magnesium, Silicon, etc.)

Aluminium 6061-T6 contains magnesium and silicon as primary alloying elements, with traces of iron, copper, and chromium. Magnesium enhances strength and corrosion resistance, while silicon improves castability and reduces thermal expansion. Chromium adds strength and resistance to corrosion, making the alloy versatile for structural applications. These elements combine to achieve a balance of mechanical and physical properties.

2.2 Chemical Composition Limits and Standards

Aluminium 6061-T6 adheres to strict chemical composition limits defined by ASTM B209 and AMS QQ-A-250/8 standards. Key elements include magnesium (0.8-1.2%), silicon (0.4-0.8%), iron (≤0.5%), copper (≤0.15%), chromium (0.15-0.35%), and zinc (≤0.25%). These limits ensure consistency, strength, and corrosion resistance, making it suitable for aerospace, automotive, and structural applications.

Physical Properties of Aluminium 6061-T6

Aluminium 6061-T6 exhibits a density of 2.7 g/cm³, high thermal conductivity (172 W/m-K), and specific heat capacity (897 J/kg·K). Its melting range is 528-638°C.

3.1 Density and Thermal Properties

Aluminium 6061-T6 has a density of 2.7 g/cm³ and high thermal conductivity at 172 W/m·K, making it suitable for heat exchangers. Its specific heat capacity is 897 J/kg·K, and it exhibits a melting range of 528–638°C. These properties ensure excellent thermal performance in various industrial and structural applications, balancing strength with thermal management capabilities effectively.

3.2 Electrical and Thermal Conductivity

Aluminium 6061-T6 exhibits excellent electrical conductivity at approximately 40% of the International Annealed Copper Standard (IACS). Its thermal conductivity is around 170 W/m·K, making it suitable for applications requiring efficient heat dissipation. These properties, combined with its strength, make it ideal for electrical components, heat sinks, and structural parts where conductivity and durability are critical.

Mechanical Properties of Aluminium 6061-T6

Aluminium 6061-T6 offers a strong balance of mechanical properties, including high strength, durability, and resistance to fatigue, making it ideal for structural and load-bearing applications.

4.1 Tensile Strength, Yield Strength, and Elongation

Aluminium 6061-T6 exhibits a tensile strength of approximately 290-310 MPa and a yield strength of 240-260 MPa, ensuring high structural integrity. It also demonstrates an elongation at break of 10-12%, balancing strength with ductility. These properties make it suitable for applications requiring durability under stress, such as aerospace and automotive components, where reliability and performance are critical.

4.2 Hardness and Fatigue Strength

Aluminium 6061-T6 has a hardness of approximately 95 HB, providing excellent wear resistance. Its fatigue strength, around 96 MPa, ensures durability under cyclic loading conditions. These properties make it ideal for components subjected to repetitive stress, such as aircraft parts and machinery, where long-term reliability and resistance to material degradation are essential.

4.3 Shear Strength and Modulus of Elasticity

Aluminium 6061-T6 exhibits a shear strength of approximately 207 MPa and a modulus of elasticity of about 69 GPa. These properties contribute to its excellent structural integrity, making it suitable for applications requiring high stiffness and resistance to deformation under load. This combination enhances its performance in demanding engineering scenarios.

Manufacturing and Machinability

Aluminium 6061-T6 offers excellent machinability and versatility in manufacturing processes. It is easily fabricated through extrusion, forging, and machining, making it ideal for automotive and aerospace applications.

5.1 Machinability and Tooling Requirements

Aluminium 6061-T6 exhibits excellent machinability, rated as 90% compared to 2011-T3. It requires high-speed steel or carbide tools for optimal results. Proper tool geometry and coolant usage are recommended to minimize galling and ensure smooth finishes. This alloy is widely used in CNC machining for precision parts due to its stable mechanical properties during processing.

5.2 Weldability and Joining Techniques

Aluminium 6061-T6 is highly weldable using MIG and TIG welding techniques. It requires appropriate filler materials to maintain strength and corrosion resistance. Post-welding heat treatment, such as artificial aging, may be needed to restore T6 properties in heat-affected zones. Brazing and adhesive bonding are also effective for joining, while mechanical fasteners like bolts and rivets provide alternative solutions for non-welded applications.

Applications of Aluminium 6061-T6

Aluminium 6061-T6 is widely used in aerospace, automotive, and construction industries due to its high strength, durability, and corrosion resistance, making it ideal for structural components.

6.1 Aerospace and Aircraft Industry Applications

Aluminium 6061-T6 is extensively used in the aerospace sector for aircraft structures, fittings, and components due to its high strength-to-weight ratio, corrosion resistance, and weldability. It is ideal for applications requiring durability and lightweight properties, such as wing components, helicopter parts, and satellite hardware, making it a preferred choice for both civilian and defense aerospace applications.

6.2 Automotive and Transportation Equipment

Aluminium 6061-T6 is widely used in automotive and transportation applications due to its excellent mechanical properties and corrosion resistance. It is utilized in vehicle frames, engine components, and structural parts. Its lightweight nature reduces fuel consumption while maintaining strength, making it ideal for automotive manufacturing. Additionally, it is used in rail and marine transportation for durable and high-performance components.

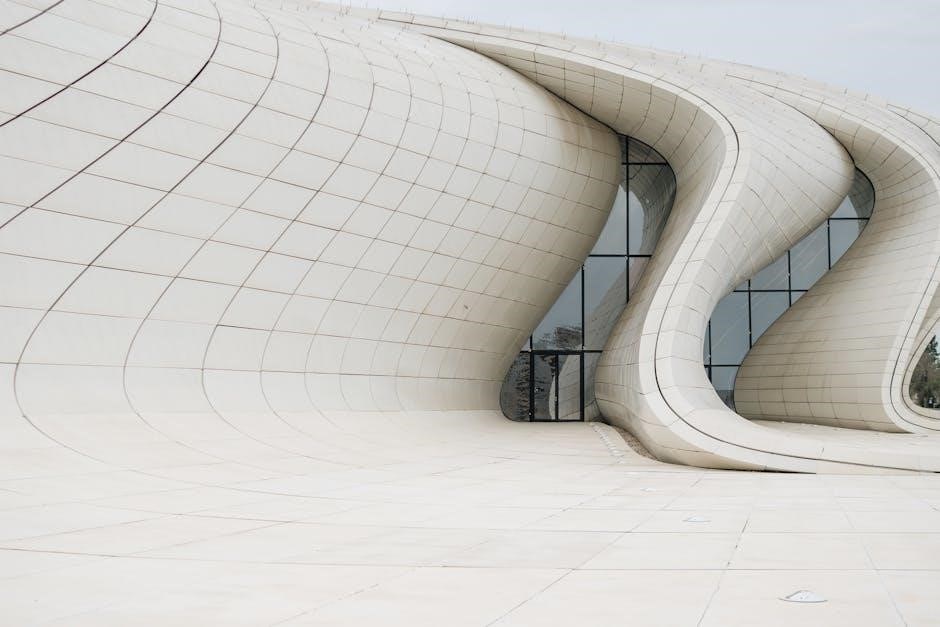

6.3 Construction and Architectural Uses

Aluminium 6061-T6 is widely used in construction and architecture due to its high strength-to-weight ratio, corrosion resistance, and durability. It is employed in structural components, load-bearing parts, and outdoor fixtures. Its aesthetic appeal and ability to withstand harsh environments make it ideal for architectural features, facades, and decorative elements, ensuring long-term performance and sustainability in building applications.

Heat Treatment and Temper Designations

Aluminium 6061-T6 undergoes heat treatment to achieve the T6 temper, involving solution heat treatment and artificial aging, resulting in high mechanical properties and stability.

7.1 Understanding the T6 Temper

The T6 temper is the most common condition for Aluminium 6061-T6, achieved through solution heat treatment and artificial aging. This process enhances mechanical properties, providing high strength, hardness, and stability. The T6 condition offers excellent resistance to fatigue and stress corrosion, making it ideal for structural applications in aerospace and automotive industries. It ensures optimal performance under harsh conditions.

7.2 Heat Treatment Process and Its Effects

The heat treatment process for Aluminium 6061-T6 involves solution heat treatment at 530°C, water quenching, and artificial aging at 160°C. This enhances mechanical properties like strength, hardness, and stability. The process refines grain structure, improves corrosion resistance, and minimizes residual stresses, ensuring the alloy performs optimally in high-stress environments while maintaining ductility and weldability.

Corrosion Resistance and Environmental Factors

Aluminium 6061-T6 exhibits excellent corrosion resistance due to its natural oxide layer, making it suitable for marine and outdoor environments. Its resistance to environmental factors like humidity and saltwater enhances durability.

8.1 Corrosion Resistance in Various Environments

Aluminium 6061-T6 demonstrates excellent corrosion resistance in marine environments, outdoor exposures, and industrial settings. Its natural oxide layer protects against humidity, saltwater, and chemical exposure. Resistance to stress corrosion cracking and pitting enhances its reliability in harsh conditions, making it suitable for diverse applications requiring durability and environmental resilience.

8.2 Coatings and Surface Treatments for Enhanced Protection

Aluminium 6061-T6 can be further protected with coatings like anodizing, powder coating, or chemical conversion. Anodizing creates a durable oxide layer, enhancing corrosion and wear resistance. These treatments are widely used in aerospace and automotive industries to ensure long-term performance in demanding environments, offering cost-effective and environmentally friendly solutions for extended material lifespan.

Durability and Longevity

Aluminium 6061-T6 exhibits excellent resistance to fatigue and stress, ensuring prolonged service life in challenging conditions. Its durable nature makes it ideal for long-term structural applications.

9.1 Fatigue Strength and Resistance to Wear

Aluminium 6061-T6 demonstrates exceptional fatigue strength, with a endurance limit of approximately 70-80 MPa, making it highly resistant to cyclic loading. Its resistance to wear and tear is enhanced by its hardened T6 temper, ensuring durability in high-stress environments. This alloy’s ability to withstand repetitive stress without failure makes it a reliable choice for long-term structural applications.

9.2 Long-Term Performance in Harsh Conditions

Aluminium 6061-T6 retains its structural integrity and durability over extended periods in harsh environments. Its corrosion resistance and ability to withstand extreme temperatures ensure consistent performance. The alloy excels in outdoor and high-stress applications, maintaining dimensional stability and resisting degradation. This makes it ideal for industries requiring long-term reliability in challenging conditions.

Cost and Availability

Aluminium 6061-T6 is cost-effective compared to high-performance alloys, offering good strength-to-cost ratio. It is widely available globally, meeting high industrial demands with stable market supply and distribution.

10.1 Cost-Effectiveness of Aluminium 6061-T6

Aluminium 6061-T6 offers excellent cost-effectiveness, balancing moderate pricing with high performance. Its strength, durability, and corrosion resistance make it ideal for aerospace and automotive applications, reducing long-term maintenance costs. This alloy provides a strong return on investment, especially in demanding environments where reliability is critical.

10.2 Global Availability and Market Trends

Aluminium 6061-T6 is widely available globally, with major producers in Asia-Pacific, North America, and Europe. Its demand is driven by aerospace, automotive, and construction industries. Market trends show steady growth due to its versatility and lightweight properties, with emerging markets in renewable energy and electric vehicles further boosting its popularity and production volumes worldwide.

Industry Standards and Specifications

Aluminium 6061-T6 meets key industry standards, including ASTM B209 and B308, guaranteeing consistent quality and reliability in its manufacturing and diverse applications worldwide.

11.1 Relevant ASTM, EN, and Other Standards

Aluminium 6061-T6 complies with multiple industry standards, including ASTM B209, B308, and EN 485, which outline specifications for wrought aluminium alloys. ISO 6361 also applies, covering dimensional tolerances. These standards ensure the alloy meets strict mechanical and chemical requirements, guaranteeing quality and reliability across its applications.

11.2 Compliance with International Regulations

Aluminium 6061-T6 complies with international regulations such as RoHS and REACH, ensuring environmental and safety standards. It meets aerospace and automotive certifications, making it suitable for global markets. Its durability and recyclability align with sustainability goals, further enhancing its compliance with global environmental directives and industry-specific requirements.

Comparisons with Other Aluminium Alloys

Aluminium 6061-T6 offers a balanced combination of strength, corrosion resistance, and weldability, distinguishing it from alloys like 6061-T4, 6005A, and 7075-T6, with varied applications.

12.1 Comparison with 6061-T4 and Other Tempers

Aluminium 6061-T6 differs from 6061-T4 in its heat treatment process, with T6 being artificially aged for higher strength and stability. T4 has lower tensile strength but higher elongation, making it more formable. Other tempers like T6511 offer similar properties to T6 but with stress-relieved characteristics. Each temper is suited for specific applications based on strength, formability, and stability requirements.

12.2 Differences from 6005A and Other Similar Alloys

Aluminium 6061-T6 differs from 6005A in alloying elements and mechanical properties. 6061-T6 contains magnesium and silicon, offering higher tensile strength and corrosion resistance, while 6005A has lower strength but better formability. Other similar alloys like 6063-T6 are less strong but more corrosion-resistant. Each alloy’s composition and temper tailor its performance for specific applications.

Sustainability and Environmental Impact

Aluminium 6061-T6 is highly recyclable, reducing environmental impact. Its lightweight nature enhances fuel efficiency in vehicles, lowering emissions. Durable properties minimize resource consumption over time.

13.1 Recycling and Reusability of Aluminium 6061-T6

Aluminium 6061-T6 exhibits high recyclability, retaining its properties after recycling. Its durability and resistance to corrosion make it ideal for reuse in various applications. Recycling reduces energy consumption and environmental impact compared to producing new material. This alloy’s reusability contributes to sustainable practices, aligning with green manufacturing goals and reducing waste in industries like aerospace and automotive.

The alloy’s ability to maintain structural integrity post-recycling ensures its performance remains consistent. Industries benefit from cost savings and reduced resource depletion by reusing Aluminium 6061-T6, further enhancing its sustainability profile.

13.2 Environmental Benefits of Using Aluminium Alloys

Aluminium alloys, including 6061-T6, offer significant environmental benefits. Their high strength-to-weight ratio reduces material usage and lowers emissions in transportation. Durable and resistant to corrosion, they require less maintenance and replacement, minimizing resource consumption. Aluminium’s recyclability promotes a circular economy, conserving raw materials and reducing waste. These factors make aluminium alloys a sustainable choice for various industries.

Aluminium 6061-T6 excels due to its high strength, corrosion resistance, and versatility, making it a top choice for aerospace, automotive, and construction. Its future prospects remain strong.

14.1 Summary of Key Properties and Applications

Aluminium 6061-T6 is a versatile alloy known for its high strength, corrosion resistance, and weldability. It excels in aerospace, automotive, and construction due to its excellent mechanical properties. Its T6 temper ensures peak hardness and strength, making it ideal for structural components. Widely used in aircraft parts, bike frames, and marine hardware, it balances durability and cost-effectiveness, ensuring long-term reliability in diverse applications.

14.2 Future Prospects for Aluminium 6061-T6

Aluminium 6061-T6 is poised for growth in emerging industries like electric vehicles and renewable energy systems. Its lightweight and corrosion-resistant properties make it ideal for advanced applications. Research into new manufacturing techniques, such as 3D printing, could further enhance its usability. Additionally, advancements in surface coatings may improve its durability in harsh environments, ensuring its relevance in future technologies.

References and Further Reading

For detailed technical insights, refer to ASTM B221 and B241 standards for specifications. The Aluminum Association and SAE publications provide comprehensive guides on 6061-T6 properties and applications.

- ASM Handbook: Properties and Selection of Aluminum Alloys.

- Research articles on fatigue and corrosion resistance in 6061-T6.

- Technical datasheets from leading manufacturers like Alcoa.

Visit aluminum.org or saemobilus.org for downloadable resources and in-depth studies.

15.1 Key Datasheets and Technical Resources

Essential datasheets for Aluminium 6061-T6 properties are available from ASTM, EN, and ISO standards. Technical resources include material safety datasheets (MSDS) and supplier specifications. Major manufacturers like Alcoa and Rio Tinto provide detailed PDF guides. These documents outline mechanical, thermal, and chemical properties, ensuring compliance with international standards for engineering applications. They are indispensable for design and manufacturing professionals.

15.2 Recommended Literature for In-Depth Study

For comprehensive analysis, refer to the ASM Handbook Volume 2: Properties and Selection of Aluminum Alloys. Additional resources include Aluminum: Properties and Physical Metallurgy by J.E. Hatch and ASTM standards like B209 and B308. These provide detailed insights into mechanical properties, corrosion resistance, and applications of 6061-T6.

No Responses